1.Need Insight Mechanism

Industry expert team conducts on-site research of client application scenarios

Establishes a three-dimensional needs analysis model (functional requirements / environmental parameters / cost budget)

Delivers Product Development Evaluation Record Form and technical parameter comparison tables

2.Solution Recommendations

Visual comparison of core performance indicators (abrasion resistance / temperature resistance / compression set resistance, etc.)

Organizes industry experts to conduct finite element stress analysis, operating condition analysis, and core pain point analysis for products

Provides at least 3 differentiated solutions based on client performance requirements

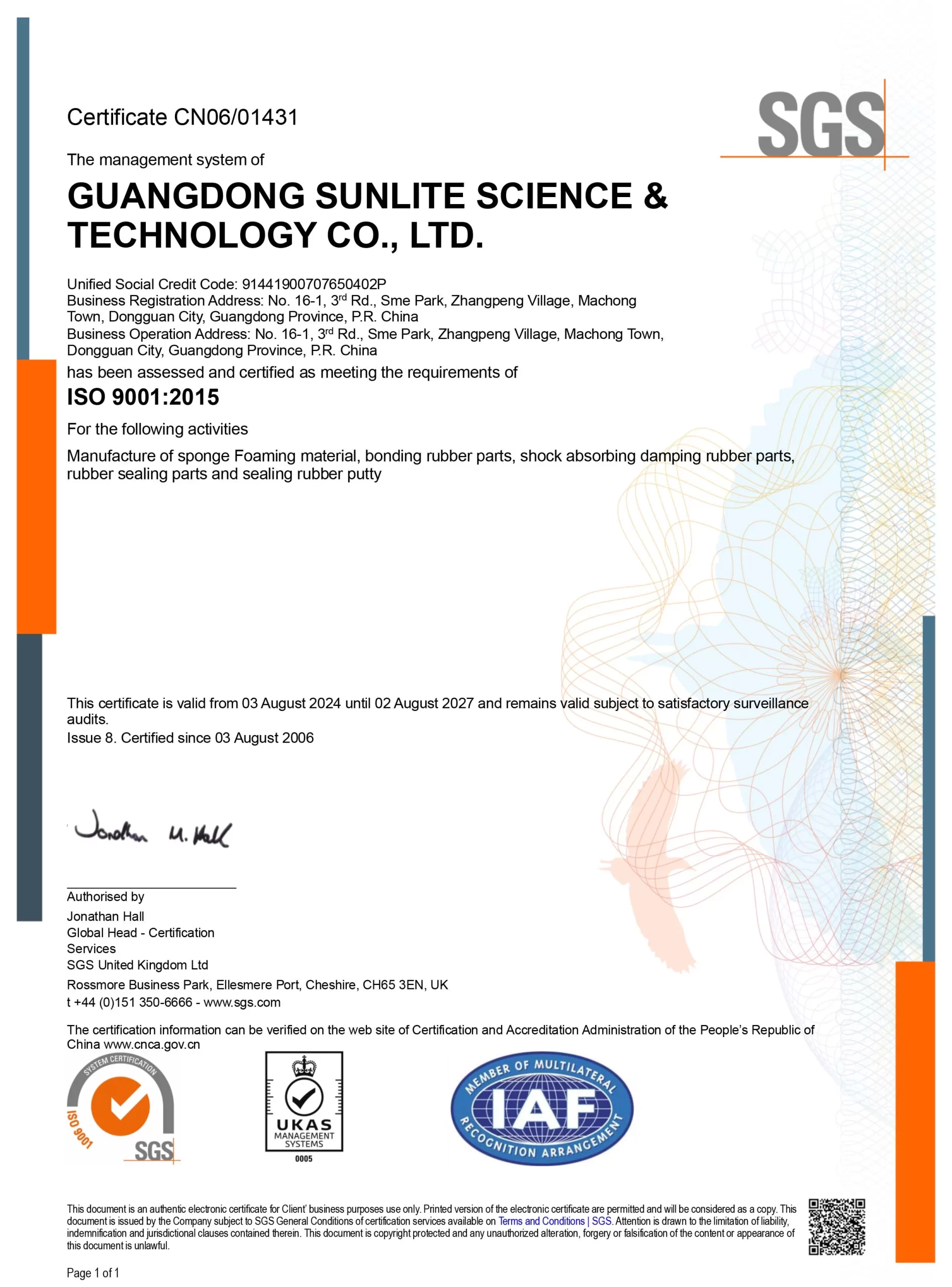

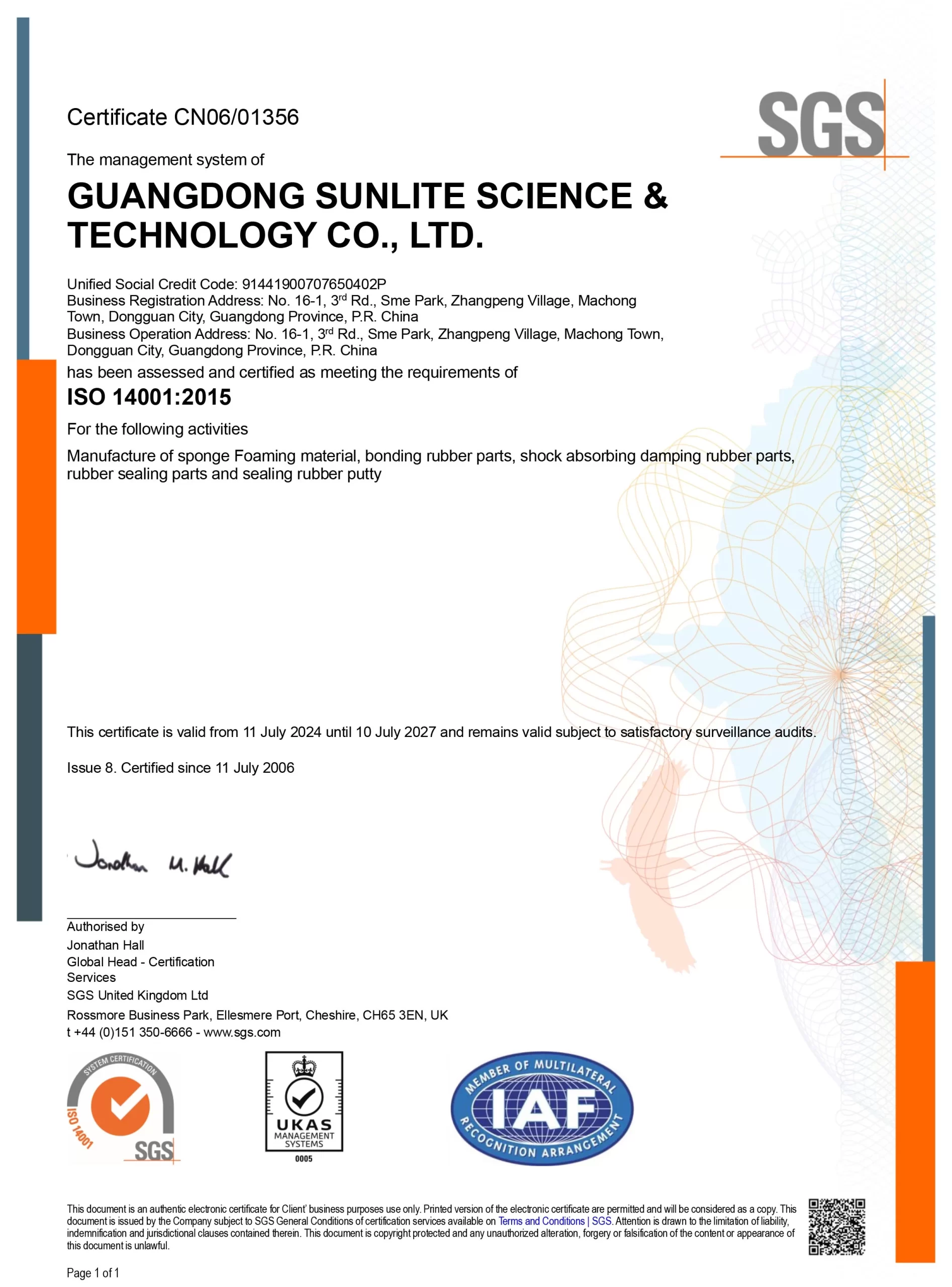

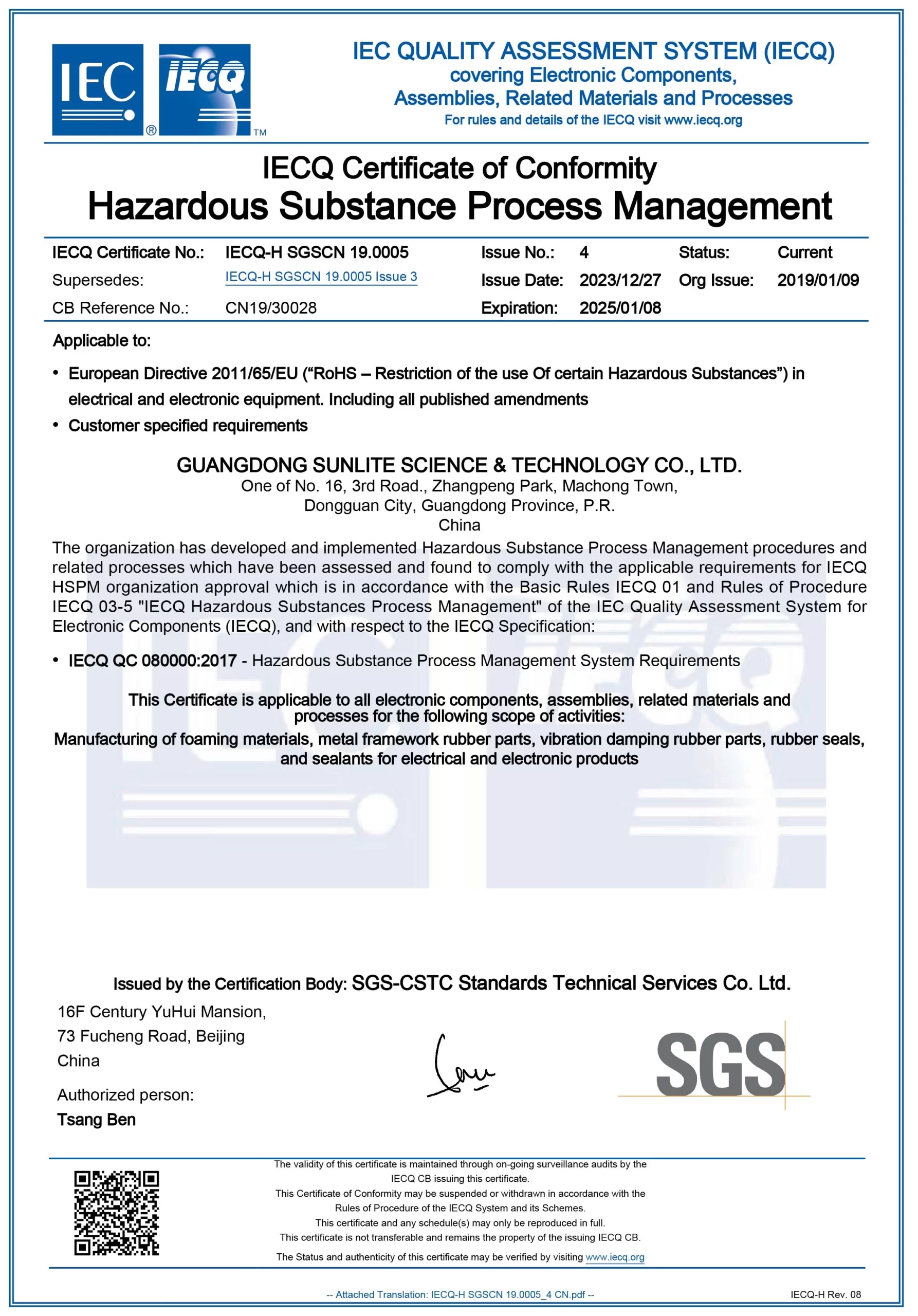

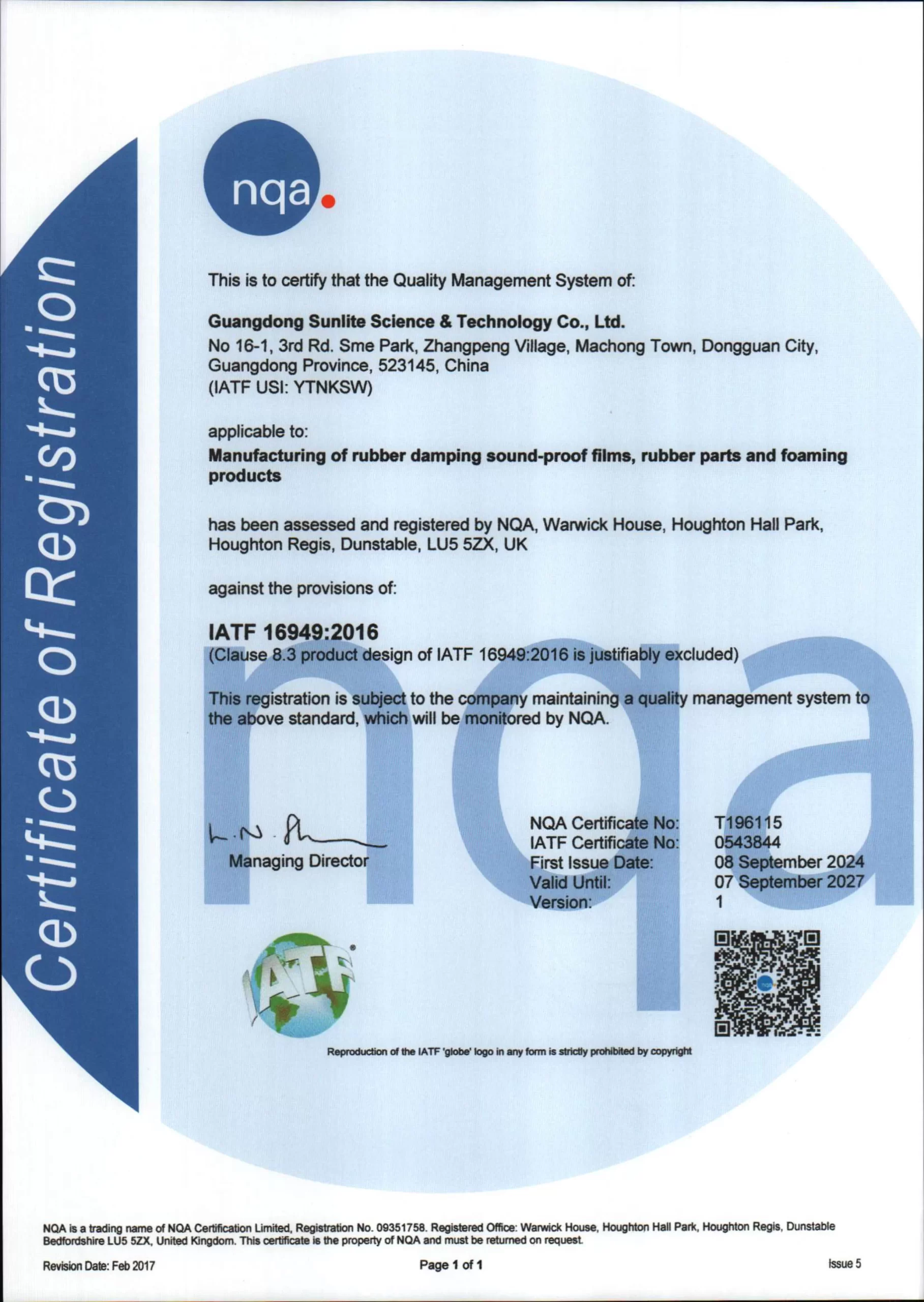

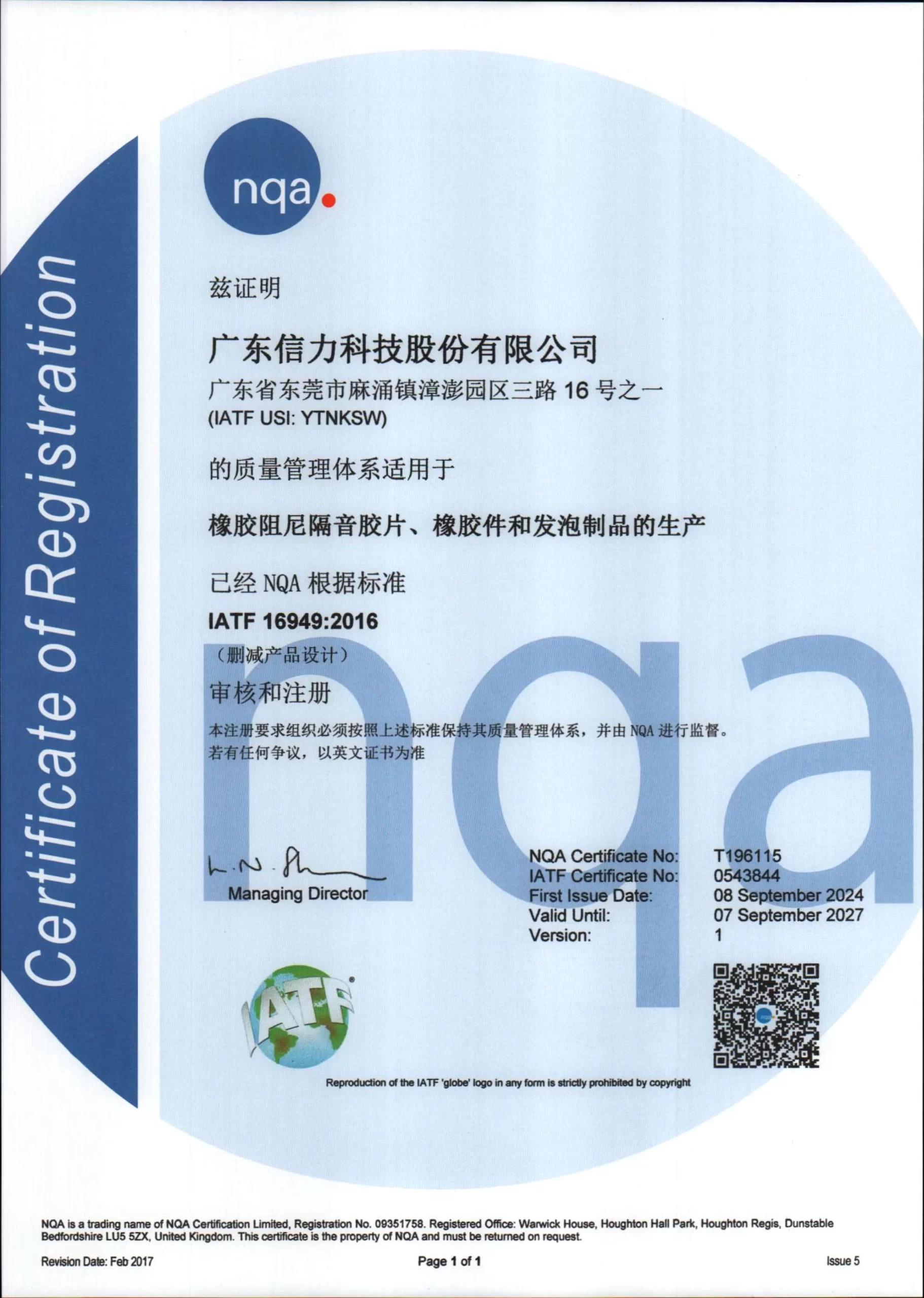

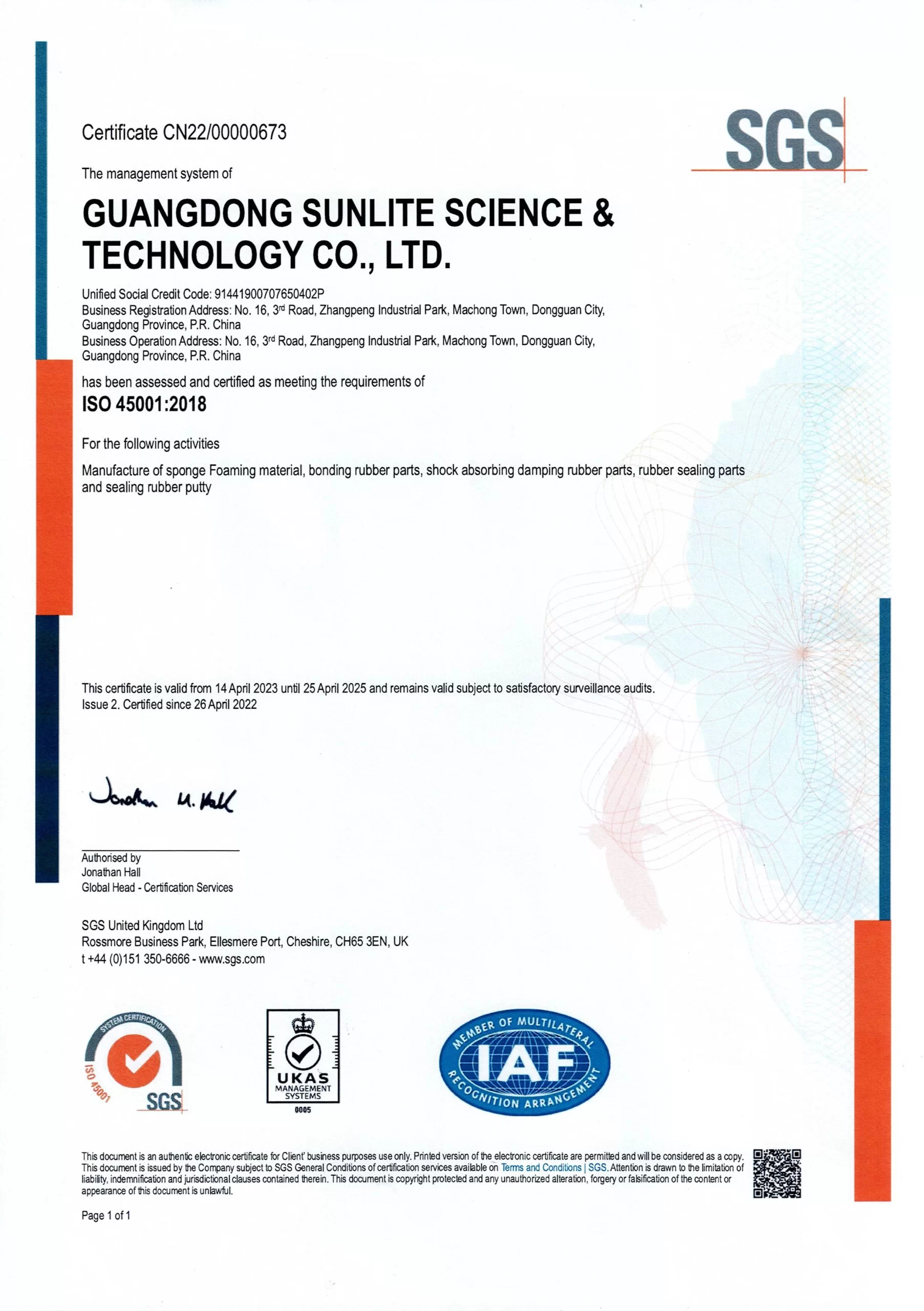

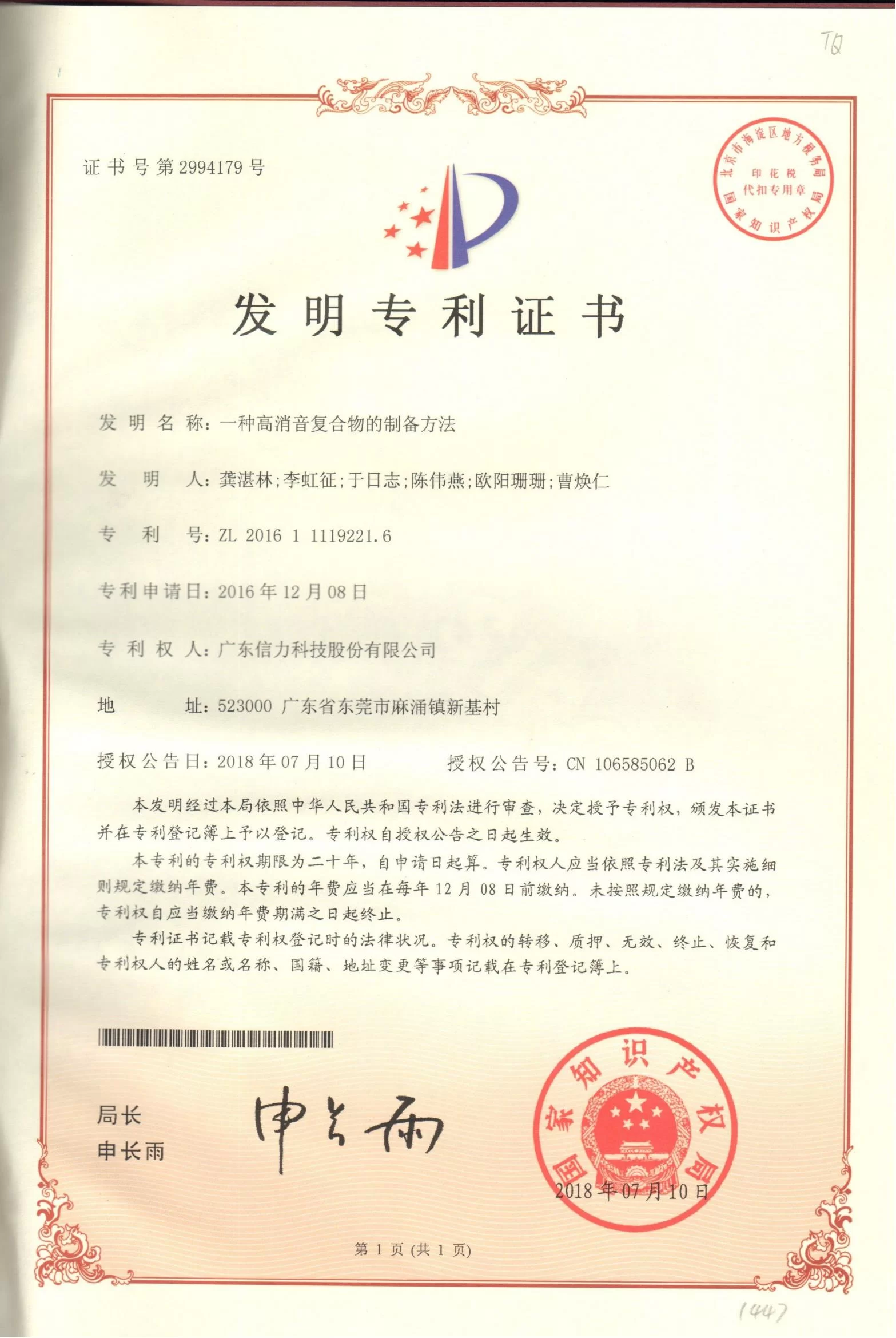

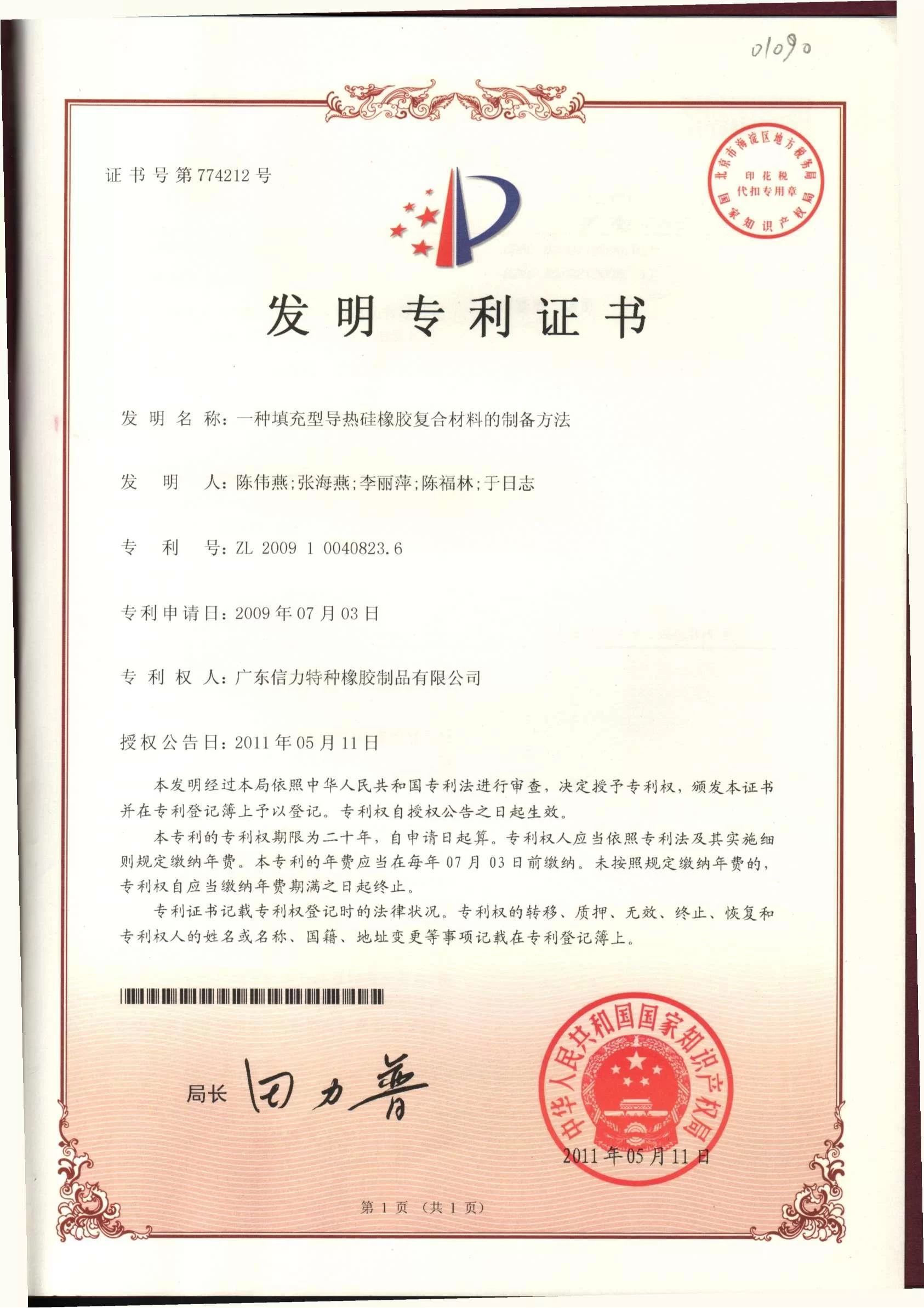

3.Quality Assurance System

Six-layer quality inspection standards (raw materials / mixing / vulcanization / dimensions / performance / appearance)

98.9% client repurchase rate validates our quality promise

4.Rapid Response Mechanism

8-hour inquiry response (including professional technical answers)

4-day express prototyping (in-house mold workshop and dedicated mold design/manufacturing team for rapid turnaround)

7–14-day delivery cycle (supports green channels for urgent orders)

48-hour complaint response (provides investigation reports and clear resolution plans)

5.Value-Added Service Package

Free technical training (online + offline)

7×24-hour lifetime maintenance consultation

Select Language

Select Language